sodium hyaluronate gel injection has gained significant attention in the medical industry due to its numerous benefits and applications. This article aims to explore the industry trends and analysis related to sodium hyaluronate gel injection, highlighting its effectiveness and quality assurance processes.

Increasing Demand for Sodium Hyaluronate Gel Injection

In recent years, there has been a surge in demand for sodium hyaluronate gel injection as a non-surgical solution for various medical conditions. The gel is known for its ability to provide hydration, lubrication, and cushioning effects on joints affected by osteoarthritis. Additionally, it is widely used in cosmetic procedures such as dermal fillers to reduce wrinkles and enhance facial features.

Moreover, sodium hyaluronate gel injection offers long-lasting results with minimal side effects compared to other treatment options. Its biocompatibility ensures compatibility with human tissues, reducing the risk of adverse reactions or complications post-treatment.

The Role of Quality Assurance Processes

To ensure the safety and efficacy of sodium hyaluronate gel injections, stringent quality assurance processes are implemented throughout manufacturing and distribution. These processes involve rigorous testing methods that assess product purity, sterility, stability, and consistency.

Manufacturers adhere to Good Manufacturing Practices (GMP) guidelines set by regulatory authorities to maintain high-quality standards during production. They conduct thorough inspections at each stage of manufacturing – from raw material sourcing to final packaging – ensuring that only safe products reach healthcare professionals.

Furthermore, quality control measures extend beyond production facilities. Distributors play a crucial role in maintaining product integrity during transportation and storage by adhering to proper handling protocols such as temperature control requirements.

The Advancements in Medical Sodium Hyaluronate Gel

medical sodium hyaluronate gel, specifically formulated for therapeutic purposes, has witnessed significant advancements. The gel’s molecular weight and concentration are tailored to meet the specific needs of different medical applications.

New formulations have been developed to enhance the gel’s viscoelastic properties, allowing it to effectively mimic natural joint fluids or provide optimal volume augmentation during cosmetic procedures. These advancements contribute to improved patient outcomes and overall satisfaction.

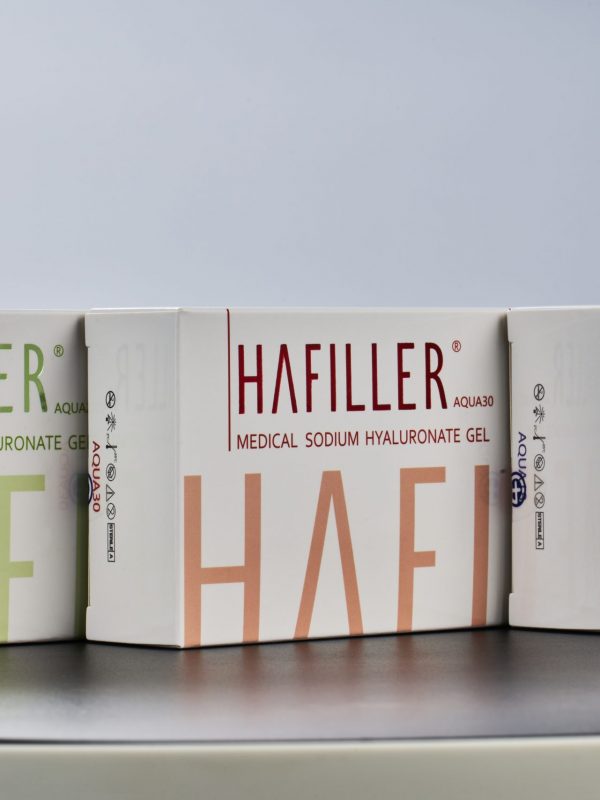

Hafiller: A Prominent Sodium Hyaluronate Gel Brand

Hafiller is a renowned brand that offers a range of high-quality sodium hyaluronate gels for various medical and aesthetic purposes. Their products undergo rigorous testing and quality assurance processes to ensure safety and efficacy.

Hafiller’s extensive research and development efforts have led to innovative solutions that address specific medical conditions such as osteoarthritis or facial rejuvenation. With their commitment to excellence, Hafiller continues to be a trusted choice among healthcare professionals worldwide.

Conclusion

Sodium hyaluronate gel injection has emerged as a popular non-surgical solution in both medical and aesthetic fields due to its effectiveness and minimal side effects. Quality assurance processes play a vital role in ensuring the safety and reliability of these injections throughout manufacturing, distribution, transportation, and storage.

The continuous advancements in medical sodium hyaluronate gels offer tailored solutions for various applications, contributing towards enhanced patient outcomes. Brands like Hafiller exemplify the industry’s dedication towards providing high-quality products that meet stringent standards while addressing specific healthcare needs.